Cutter Technologies Pte Ltd

We provide complete project prototyping and low volume production for your New Product Development . . .

Functional

Visual

Validation

Short Runs

Introduction

Cutter Technologies Pte Ltd was established in 2002 as an Industrial Prototyping and Engineering company in Singapore.

Our core business is to provide complete project support for new product development in prototyping, prototype / production tooling, assembly tooling and flexible batch / low volume production.

We have subsidiaries and partners in Singapore, Malaysia and China to enable a greater scope in manufacturing capacity and resources.

We are a member of the Singapore Medtech Consortium since September 2017. The consortium will provide end-to-end manufacturing solutions in various medtech areas, namely wearables, active and non-active medical devices, in-vitro diagnostics and life science tool consumables.

We look forward to be a valued member of your Product Design Team !

Thank you !

Services

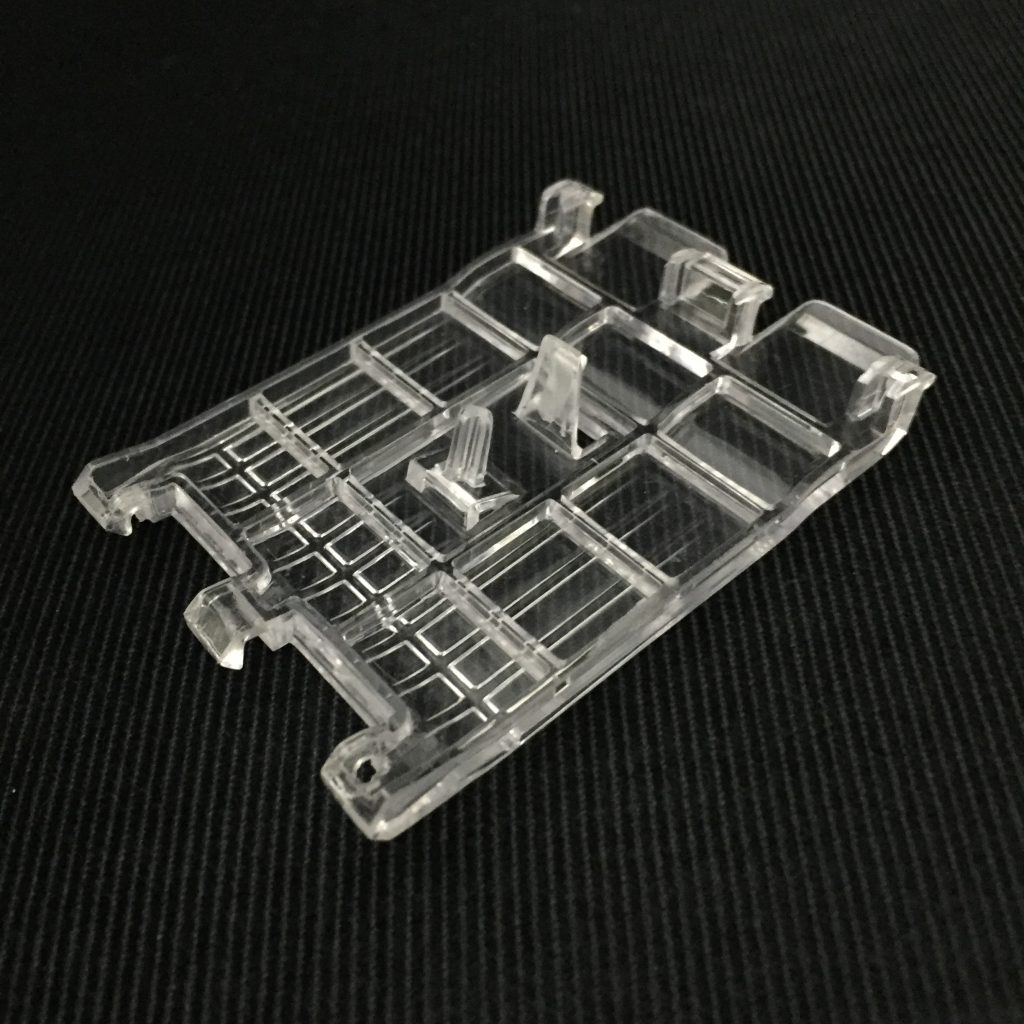

CNC Machining – Plastics

For parts that require close tolerances and precision fit or functional mechanism. CNC machined parts are also used to make Masters for Vacuum Casting using Silicone Rubber Molds. A wide range of materials are available for CNC processes which include Plastics, Metals ( Ferrous and non-Ferrous ), Hard Rubber, Wood and others.

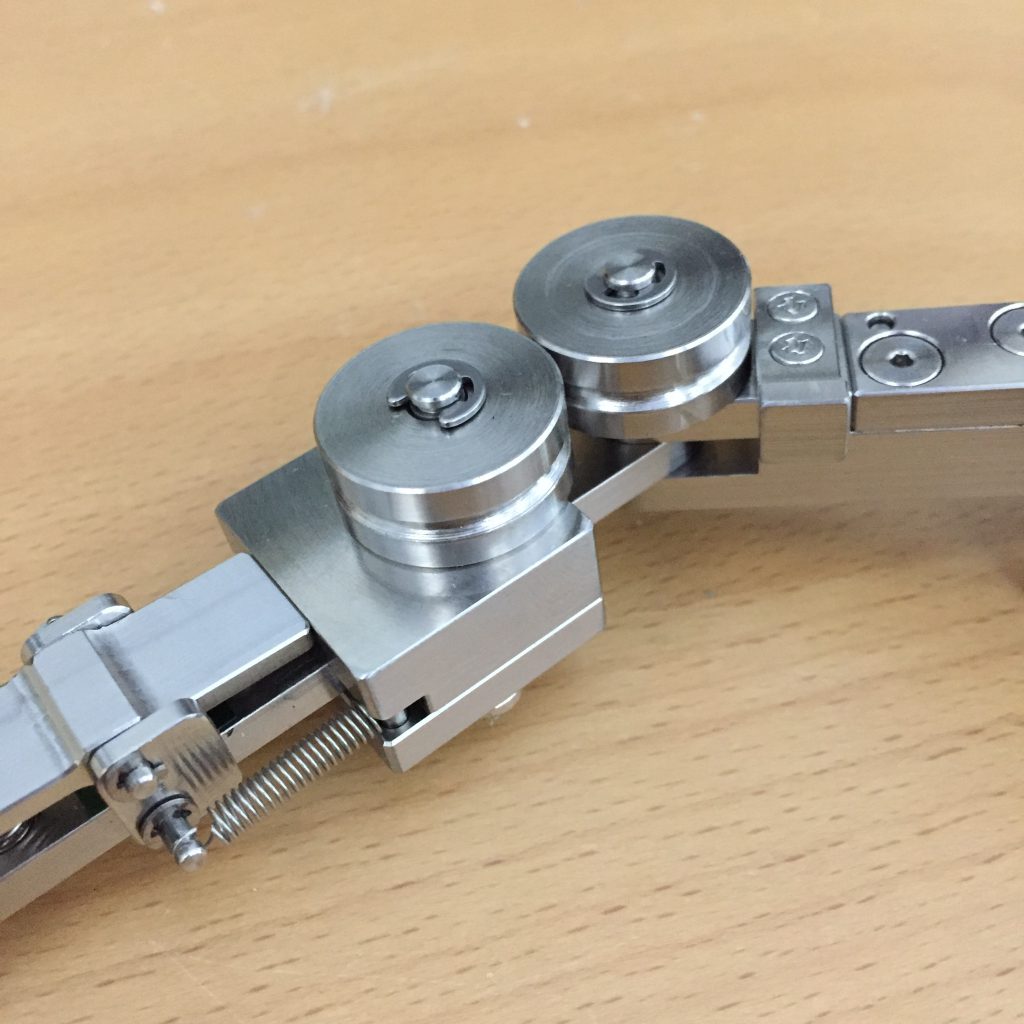

Metals Machining

Sheetmetal Prototyping

Silicone Mold and Vacuum Casting

Silicone molds are universally used in vacuum casting manufacture, using CNC master sample to produce the silicone mold and then to inject the PU casting material in a vacuum equipment to produce the finished parts. The finished parts are identical to the master copy and have the same quality with the original sample. This new technology has the advantage of fast production time and low cost, which can greatly reduce product development cycle and reducing initial cost and risk. It is particularly suitable for low-volume production.

Available materials is a range of Polyurethane (PU) grades equivalent performance close to either ABS, PC, POM, PP, and in transparent and flexible grades.

Finishing Processes

Painting, Silk-screening, Electroplating, Anodizing, Laser Etching, Sandblasting, UV Coating, and others . . .

Our Customers

and more . . .

Gallery